COMPANY

Officine Nuove srlCUSTOMISATION

The main reasons why our customers have chosen us since 1973.

PRECISION

QUALITY SERVICE AND RAW MATERIALS

We only process top quality materials to ensure the durability and performance of the products. Our production meets the quality control requirements of UNI EN 1090-1 and UNI EN ISO 9001:2015 standards.

CUSTOMISATION

MADE-TO-ORDER PRODUCTS

We are efficiently organised to handle large and small orders, and can help you find the best solution thanks to the support of our experienced technical staff and the optimization of our different production lines.

PUNCTUALITY

TIMELY DELIVERY OF ALL ORDERS

With our plant covering an area of 4,500 square metres divided into three different production areas (sheet metal working, metal fabrication and custom-made products) and our large warehouse, we can efficiently manage production and ensure timely deliveries.

CONSTRUCTION AND METAL WORK

PROJECT MANAGEMENT

Our extensive and well-established network of partnerships – the result of decades of experience in light construction and metalwork – allows us to select the best craftsmen for the supply of finished products. Our range of special services includes welding, galvanisation and painting.

FOUNDED IN

CUSTOMERS

MATERIAL PRODUCED

PRODUCTS

FOR OVER 50 YEARS

We have been dealing with sheet metal working and we have been meeting the requests of large companies and craftsmen.

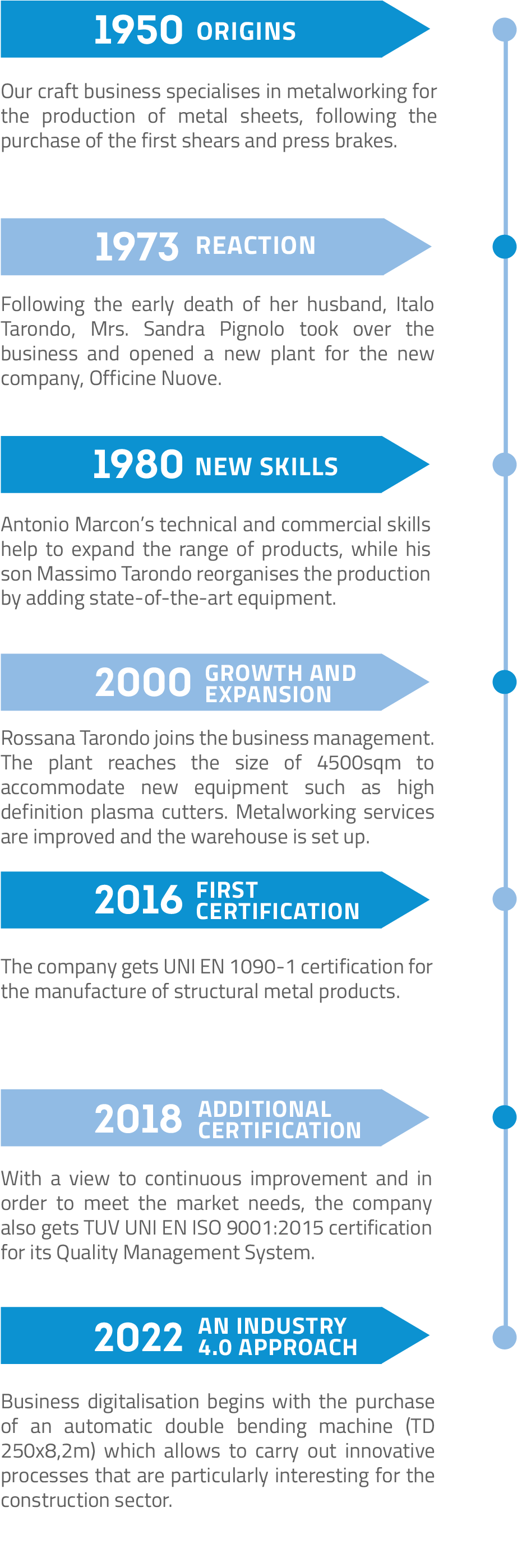

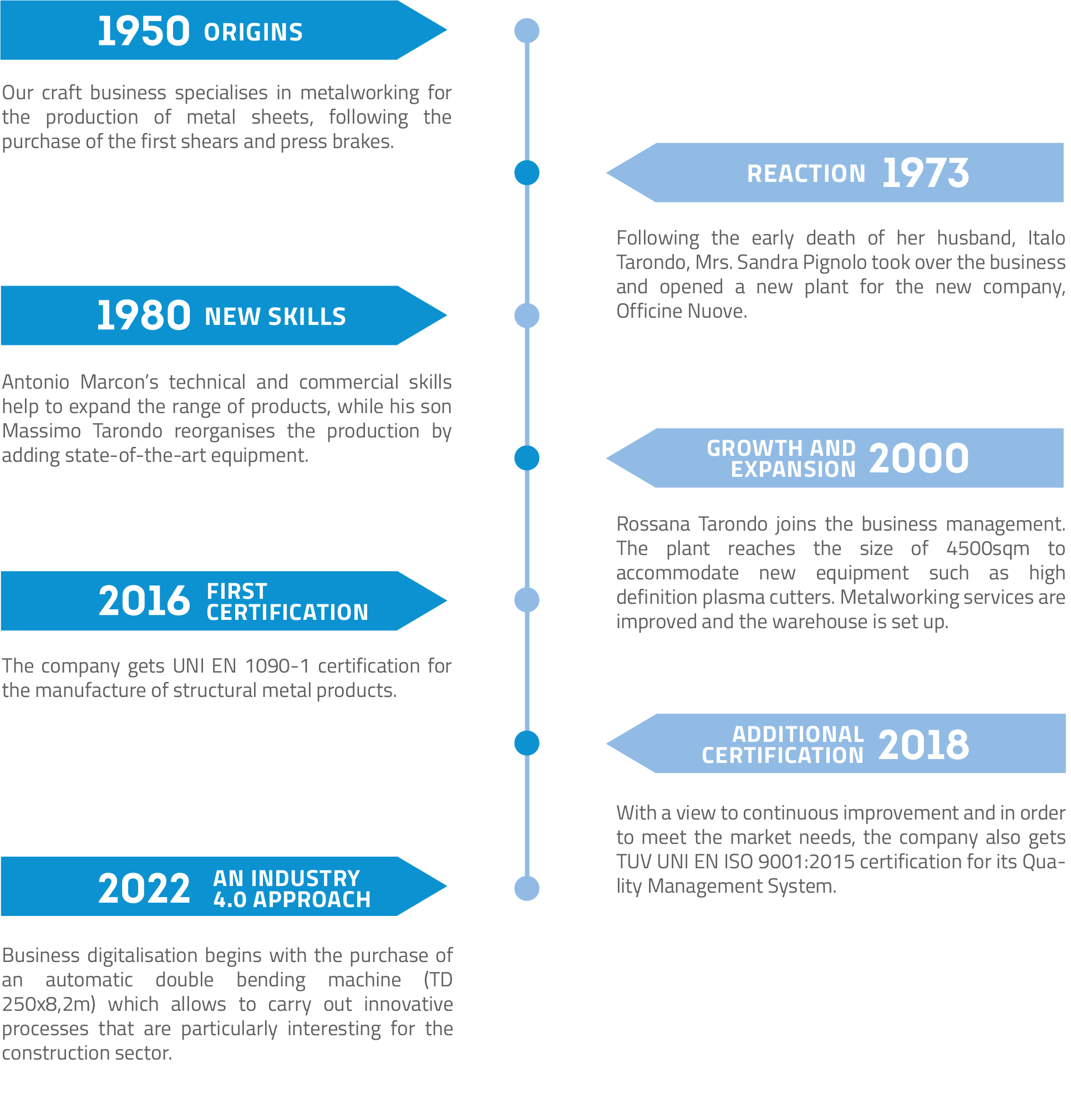

A family story: from a strong passion for craftsmanship to digital innovation.

FOR OVER 40 YEARS

We have been dealing with sheet metal working and we have been meeting the requests of large companies and craftsmen.

A family story: from a strong passion for craftsmanship to digital innovation.